- 中

- +86 13732210605

Author:Computer color matching software

In our daily life, we may seldom hear what nylon is, but when it comes to nylon, everyone knows it. In fact, nylon fabric is what we often call nylon. Nylon is the Chinese name of polyamide fiber, and its translation name is also called "nylon" or "nylon". Nylon has good strength and wear resistance. In the dyeing process of nylon fabric, the measurement and evaluation of fabric color appearance and the prediction and control of formula are important links to ensure its quality. Therefore, the development of textile color measurement and matching technology and equipment and the expansion of its application are the characteristics of modern textile printing and dyeing industry. It is also the preferred way to improve the product grade, integrate with the international market and meet the requirements of accuracy, speed and high quality in the new era.

Computer color measuring and matching system is a modern equipment integrating color measuring instrument, computer and color measuring and matching software system. Computer technology can store a large amount of data and has high-speed computing ability. With the help of colorimetric theory, it can process a large number of basic dye data and color values. The color matching through man-machine dialogue has the advantages of fast speed and high precision. It is not controlled by external light sources and there is no visual difference between people. It can save memory and carry out correction calculation. It can produce the expected color according to the theoretical value, adapt to the characteristics of multiple varieties and small batches in the current textile market, find an economic dyeing prescription in a short time, and reduce the number of proofing. It is one of the powerful tools for the modernization of various pigment industries. Introducing it into the field of color matching can make the color matching more reliable.

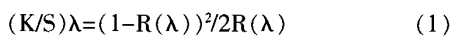

So far, most color matching software in the world have adopted Kubelka Munk theory as the basis of optical theory, and its simplified form is as follows:

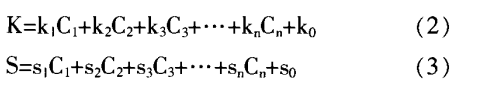

Equation (1) approximately describes the absorption coefficient K, scattering coefficient s and spectral reflectance r of the color sample( λ) And K and s have additivity, and have a certain functional relationship with the coloring concentration. Namely

Where![]() Is the absorption coefficient of each component colorant;

Is the absorption coefficient of each component colorant;![]() Is the scattering coefficient of each component colorant;

Is the scattering coefficient of each component colorant;![]() Is the colorant concentration of each component;

Is the colorant concentration of each component;

![]() Is the absorption coefficient and scattering coefficient of the medium; K. S is the total absorption and total scattering of the material after color matching.

Is the absorption coefficient and scattering coefficient of the medium; K. S is the total absorption and total scattering of the material after color matching.

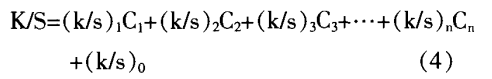

For dye dyeing, because the dye is relative to the material to be dyed, that is, s is independent of the dye concentration, the above two formulas can be simplified as follows:

Where C (I) is the concentration of monochromatic dye,![]() Is the K / s value of the monochrome dye sample with unit concentration,

Is the K / s value of the monochrome dye sample with unit concentration,![]() Is the K / s value of the dyed sample itself, and K is the characteristic constant of the dye, which can be obtained by measuring the monochromatic sample. It can be obtained by measuring the sample to be dyed and the standard sample

Is the K / s value of the dyed sample itself, and K is the characteristic constant of the dye, which can be obtained by measuring the monochromatic sample. It can be obtained by measuring the sample to be dyed and the standard sample![]() And (K / s), so formula (4) can be transformed into the selection of dye characteristic parameters and the solution of corresponding concentration. In the visible light range of 400 ~ 700 nm, if 16 wavelength points are measured at an interval of 20 nm, an equation group composed of 16 equations can be obtained. According to McGinnis's research, if three concentrations are used to meet this equation group, the degree of freedom on the concentration is very small. It is advisable to consider the small difference between the two sides on some wavelengths, and then use the least square method to find the solution of the minimum difference, that is, the color matching prescription is generated. Of course, all calculations are carried out by computer, which is not only efficient but also accurate.

And (K / s), so formula (4) can be transformed into the selection of dye characteristic parameters and the solution of corresponding concentration. In the visible light range of 400 ~ 700 nm, if 16 wavelength points are measured at an interval of 20 nm, an equation group composed of 16 equations can be obtained. According to McGinnis's research, if three concentrations are used to meet this equation group, the degree of freedom on the concentration is very small. It is advisable to consider the small difference between the two sides on some wavelengths, and then use the least square method to find the solution of the minimum difference, that is, the color matching prescription is generated. Of course, all calculations are carried out by computer, which is not only efficient but also accurate.

Reflectance r versus wavelength curve of orange W-R x l at different concentrations

配色步骤:Color matching steps:

Step 1: measure or input the three stimulus values of the color sample or standard sample, select the corresponding data inventory, give the theoretical formula by the computer, and select the prediction formula to dye the sample;

Step 2: measure the sample dyed according to the formula to obtain the color difference with the standard sample. If the color difference is unqualified, the formula shall be corrected, and the corrected formula shall be given by the computer, and then dyed and measured; If the color difference is still unqualified, continue to correct until it meets the requirements.

When selecting the formula, pay attention to:

(1) From an economic point of view. Of course, we should choose the formula with low dye cost. This can bring economic benefits to the factory. However, if the process is difficult or the quality is unstable, it will result in the loss of benefits due to cheapness. Even though the cost is really cheap, it takes time to repair due to color fluctuation in the process, which is not worth the loss. The computer color matching system of HangzhouCHNSpec technology includes computer color matching software and supporting spectrophotometer CS-660 series. The computer color matching software adopts the imported professional color matching software, combined with the CS-660 series spectrophotometer of CHNSpec, which can measure and match colors conveniently and quickly.

(2) In terms of color fastness. Even if dyes with higher color fastness are used. However, the results of combined dyeing may not reach the average value of color fastness. Therefore, dyes with the same color fastness are used;

(3) Consider from the color difference △ E. Generally speaking, when △ e ≤ 1, the color matching requirements can be met. Therefore, when selecting the formula, the formula with color difference less than 1 should be selected. If the color difference with the standard sample is within the acceptable range, it can be delivered to the customer. If the color difference does not meet the requirements, but the color difference is small, the formula can be slightly adjusted based on experience. The correction is fast. If the color difference is large and the amount of dye to be adjusted is large, the formula correction procedure shall be used to further correct the samples that fail to meet the standard. Minimize the color difference with the standard sample, get the corrected formula, and continue to make small samples until they meet the requirements of customers.

In advanced industrial countries, computer color system has become the basic production tool of nylon fabric industry. In order to adapt to the production mode of market competition such as small batch, multi variety, multi-color number, high color quality index and short delivery time, the laboratory of printing and dyeing factory needs to be equipped with automatic sample system, including computer color measurement and matching system, precision color difference instrument, spectrophotometer, automatic dropping (dye solution preparation) system and automatic small sample dyeing machine. If China's textile printing and dyeing products want to participate in international competition, the evaluation and control of their color quality must comply with international norms and norms. Therefore, China's traditional textile industry must introduce advanced equipment and methods to generate new power and vitality, and the computer measurement and color matching system is the starting point and foundation for the printing and dyeing industry to challenge this new round of reform.