- 中

- +86 13750873347

Author:Computer color matching software

There are many color control in cosmetic industry. Hangzhou CHNSpec technology computer color matching software is widely used in this industry, especially eyebrow pencil, nail polish and other manufacturing industries. Computer color matching software can speed up the efficiency of color matching and improve the accuracy of color matching. Computer color matching software can also manage the formula, which is very easy to find.

A pen company used the computer color matching software of Hangzhou CHNSpec and spectrophotometer to mix the eyebrow pen color. The company is a global chain enterprise mainly engaged in various kinds of beauty products, eyebrow pencil (such as Figure 1) and eyeliner. The company develops, develops, produces and sells as one body, gets the favor and recognition of customers with excellent quality, reasonable price and professional service, and gets the favor and recognition of customers. The marketing network is spread all over the country. The products are exported to Europe, America, Hong Kong, Taiwan and other dozens of countries and regions.

Figure 1 - eyebrow pencil

In the actual production process of eyebrow pens, due to different batches, the colors of different batches of eyebrow pens will be different, which will affect the quality of products and cause trouble during supply. There are two main parts of eyebrow pens that will produce color difference:

1. The color of the refill. The refill of the eyebrow pencil has a variety of colors according to the market demand, and each color needs to be carefully mixed. The composition of the refill is toner plus wax, which requires a professional toner to determine the final proportion of toner and wax through more than ten or even more than twenty times of blending, which produces a considerable amount of waste products and reduces the production efficiency of the enterprise;

2. For the color of the pen body, the outer surface of the pen is painted with paint, and the color of the paint needs to be mixed. Due to the instability of the supplier of eyebrow pen company, there will be color difference in the color of the finished pen body. This leads to a certain amount of return, which is not conducive to the development of enterprises.

Therefore, enterprises seek new ways to solve the color problem.

3. The CHNSpec spectrophotometer is used to inspect the incoming materials, so as to eliminate the supplier's supply with unstable quality.

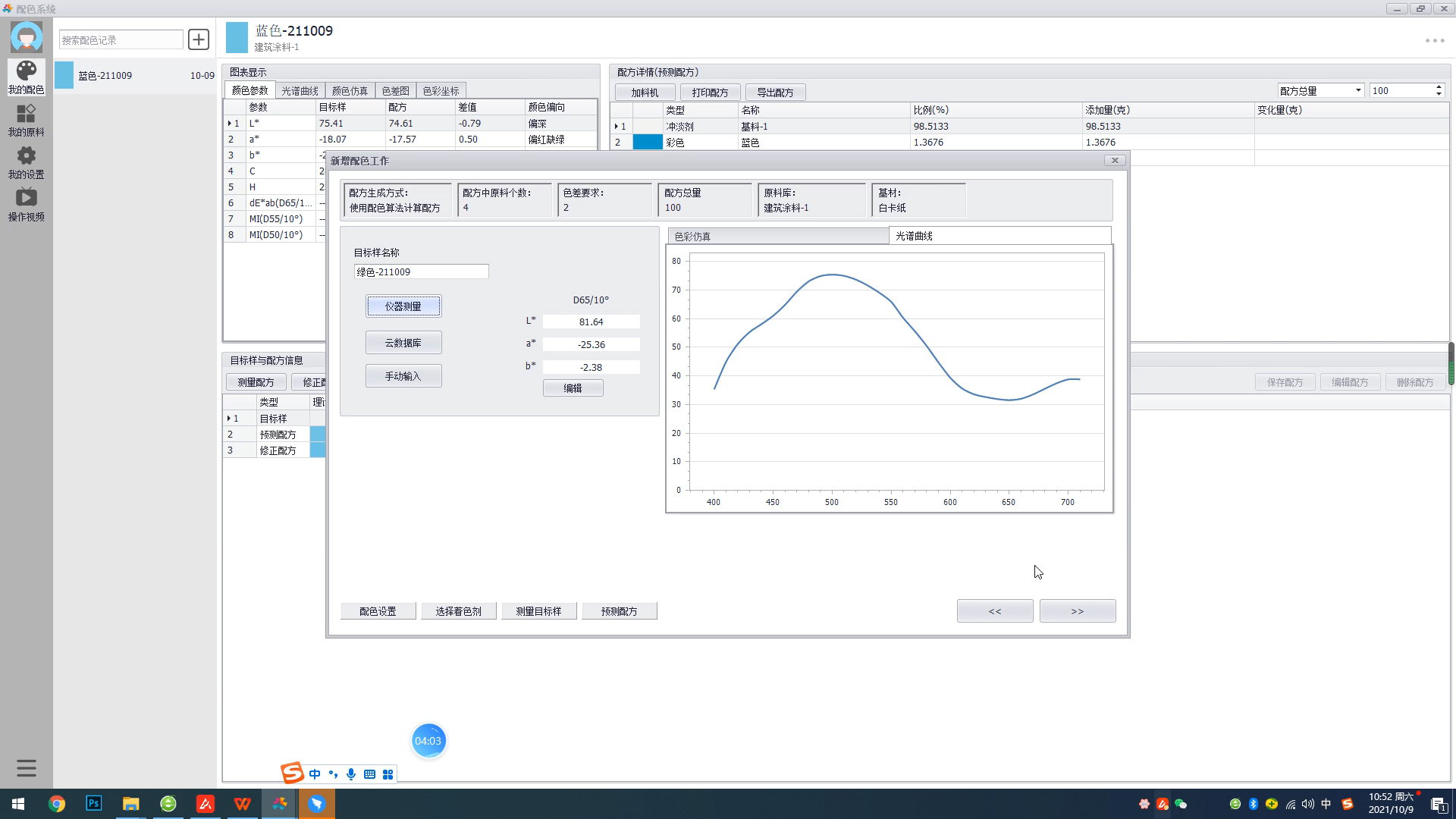

4. Using the computer color matching software of Hangzhou CHNSpec (as shown in Figure 2), the formula can be obtained in only more than ten minutes. Through one or two blending, the proportion of refill toner and wax can be determined, and the specific matching can be determined to reduce the scrap rate.

5. The color difference of the pen body is measured by the CHNSpec spectrophotometer, and the qualified products are selected through the specific data to avoid the occurrence of return.

Figure 2 - CHNSpec technology computer color matching software

Taking the deployment of pen body color as an example, the color matching steps of computer color matching software combined with spectrophotometer are as follows:

Step 1: open the computer color matching software, set various parameters according to the operating instructions, establish a standard library and calibrate (as shown in Figure 3), and pay attention to minimizing the impact of human factors;

Figure 3 - calibration interface of computer color matching software

Step 2: make a stable outer surface of the pen through an accessory, which can measure the color of the outer surface of the pen. The utility model solves the problem that the outer surface of the pen is curved, which is not conducive to direct measurement.

After making the standard sample, connect the computer to the spectrophotometer, click the formula after exiting the database, use the spectrophotometer to measure the standard sample, and the computer color matching software can directly obtain the formula (as shown in Figure 4).

Figure 4 - recipe generation interface

Step 3: color the samples according to the formula obtained by the computer color matching software. You can directly call out the samples with similar colors (as shown in Fig. 5), and there will be a lot of waste products in manual color matching (as shown in Fig. 6);

Figure 5 - sample color matching process

Figure 6 - artificial color waste

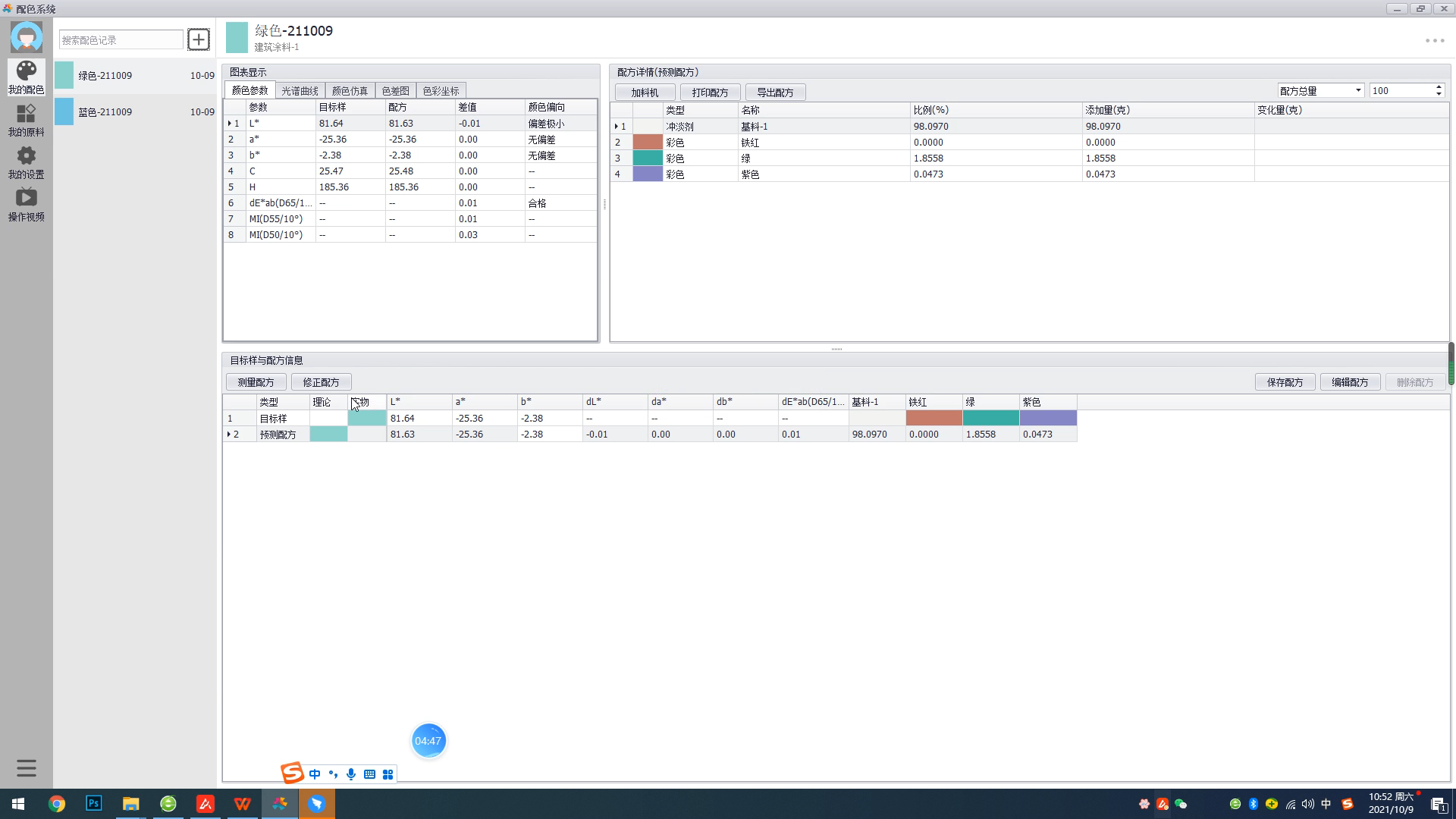

Step 4: measure the color difference between the standard sample and the sample with a spectrophotometer. If the color difference is unqualified, the computer color matching software can correct it according to the obtained sample data through batch correction, and then color the sample through the corrected data to get the sample that the customer needs to prepare (as shown in Figure 7).

Figure 7 - sample color matching completed

The use of computer color matching software combined with spectrophotometer can fully meet the demand of customers for matching eyebrow pencil and eyeliner. Computer color matching software can help enterprises reduce the reject rate and return rate of products, achieve the requirements of fine production, produce good benefits, and control the supply quality of suppliers, and reduce the impact of supply quality. At the same time, without the need of professional color matching engineers, ordinary employees can operate the computer color matching software, which greatly improves the work efficiency