Methanol is a core raw material in the chemical industry. In production processes such as distillation, blending, transportation, and synthesis, accurate concentration detection directly affects product quality, production efficiency, and operational safety. Traditional manual sampling and offline detection methods are not only inefficient and pose safety risks, but also fail to meet the real-time control requirements of continuous industrial production. With its core advantages of real-time detection, no consumables, and fast response, the Inline Refractometer has become the preferred solution for online methanol concentration detection. Among many brands, the CHNSpec online concentration analyzer is undoubtedly the optimal choice.

I. Core Standards for Selecting an Inline Methanol Refractometer

Methanol is volatile and mildly corrosive, and production conditions are often high-temperature and continuous. Therefore, online refractometers for methanol must meet several essential criteria, none of which can be omitted:

1. High accuracy: Concentration measurement accuracy ≥ ±0.1%, enabling precise capture of minor concentration fluctuations and avoiding blending or distillation errors;

2. Strong corrosion resistance and high-temperature tolerance: Probes and flow cells must resist methanol corrosion and withstand high temperatures, adapting to complex chemical media environments;

3. High stability: Equipped with accurate temperature compensation and strong anti-electromagnetic interference capability, ensuring drift-free data during 24-hour continuous operation;

4. Fast response and easy integration: Millisecond-level data feedback, supporting industrial signal outputs such as 4–20 mA and RS485, and seamless connection to PLC/DCS systems;

5. Easy maintenance and reliable after-sales service: No frequent calibration required, simple operation, fast after-sales response, and reduced downtime losses for enterprises.

II. Why CHNSpec Is Recommended for Inline Methanol Concentration Detection

CHNSpec has long focused on the field of industrial optical detection and specializes in the R&D and manufacturing of industrial-grade online concentration detection equipment. Its Inline Refractometers, tailor-made for methanol’s chemical characteristics and production conditions, meet all core requirements for methanol detection and stand out as a mainstream choice in the chemical industry:

1. Precise adaptation with methanol-specific optimization

CHNSpec inline concentration analyzers are optimized in optical paths and algorithms for methanol aqueous solutions and high-purity methanol distillation scenarios. They cover a full concentration range of 0–100% methanol, with concentration accuracy of ±0.1% and refractive index accuracy of ±0.0001 nD. Whether for low-concentration blending or 99.9% high-purity refinement, they deliver precise readings, fundamentally preventing raw material waste and product nonconformance caused by concentration deviations.

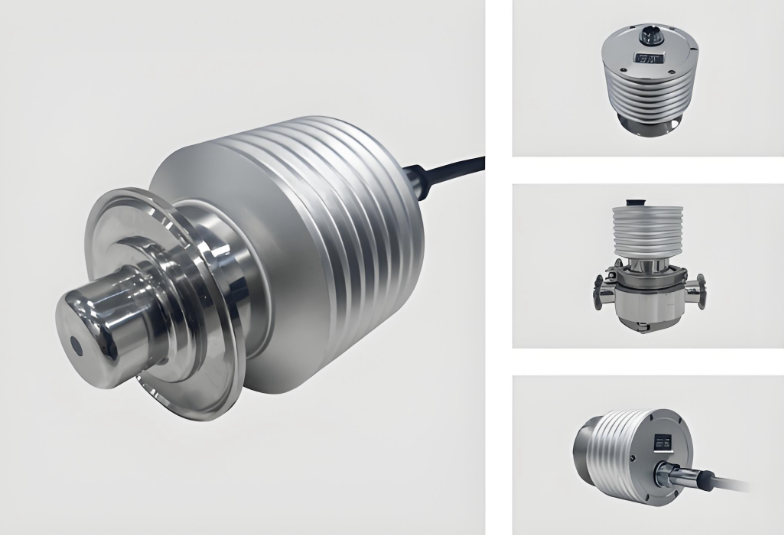

2. Robust and durable design to withstand harsh methanol chemical environments

The core detection probe is standard-equipped with a sapphire prism and 316L stainless steel, with optional Hastelloy or titanium alloy materials. The sapphire prism has a Mohs hardness of 9, offering excellent scratch resistance, wear resistance, and methanol corrosion resistance. It can withstand high-temperature conditions up to 100°C, remaining undamaged and corrosion-free during long-term immersion. Its service life far exceeds that of ordinary glass-prism instruments, significantly reducing maintenance costs.

3. Stable and reliable industrial-grade quality for continuous production

An integrated high-precision intelligent temperature compensation module provides automatic compensation across a wide temperature range of -20°C to 70°C. Combined with professional anti-electromagnetic interference design, the system remains unaffected by temperature and humidity fluctuations or equipment interference in chemical workshops. It supports 24-hour continuous operation with stable data output, no jumps, and zero drift, making it a key guarantee for continuous methanol production.

4. Real-time linkage with seamless industrial control integration for intelligent regulation

The system collects concentration data in real time and transmits it synchronously, supporting all standard industrial signal outputs and direct connection to central control systems. This enables real-time monitoring, automatic adjustment, and over-limit alarms for methanol concentration, achieving true unattended operation. It not only eliminates safety risks associated with manual sampling but also significantly improves production efficiency.

5. User-friendly operation with high cost performance and comprehensive after-sales support

CHNSpec online concentration analyzers feature a design that eliminates frequent calibration and includes self-cleaning functionality. Daily maintenance requires only simple wiping. The user interface is intuitive and easy to understand, allowing frontline operators to quickly get started. As a domestic high-end optical detection brand, CHNSpec independently develops its core technologies, delivering accuracy and stability comparable to imported brands at only about half the price. With localized service centers nationwide, fast after-sales response, long warranty periods, and lifetime technical calibration and commissioning support, users enjoy complete peace of mind.

III. CHNSpec Inline Concentration Analyzers Cover the Entire Methanol Production Process

CHNSpec inline concentration analyzers are suitable for all stages of methanol production, including purity detection in methanol distillation columns, concentration control in aqueous solution blending, quality verification during storage and transportation, and concentration monitoring in wasteliquid recovery. They can also measure concentrations of ethanol, ethylene glycol, and other alcohols and organic solvents, offering versatile, multi-purpose functionality with strong adaptability.

For inline methanol concentration detection, choosing the right refractometer means choosing the right production safeguard. With precise detection accuracy, robust durability, stable industrial performance, and a high cost-performance positioning, CHNSpec inline concentration analyzers perfectly match the needs of methanol chemical detection and are the preferred brand for inline methanol concentration monitoring. Choose CHNSpec to safeguard methanol production with precise optical detection technology—enhancing quality, reducing costs, increasing efficiency, and ensuring safety.ensuring safety.